Updates

Strong Enough for the Deepest Wells: Revolutionizing Irrigation with Idol uPVC Column Pipes

Water is the lifeblood of agriculture. For farmers across the globe, the ability to access groundwater reliably and efficiently isn’t just a convenience—it’s a necessity for survival and success. When you rely on borewells to nourish your crops, the equipment you choose to bring that water to the surface is critical. It’s not a place to cut corners.

Too often, farmers face disastrous setbacks due to borewell failures: rusted metal pipes, cracked casings, or joints that burst under pressure. These failures lead to expensive repairs, lost time, and, most devastatingly, parched crops during crucial growing seasons.

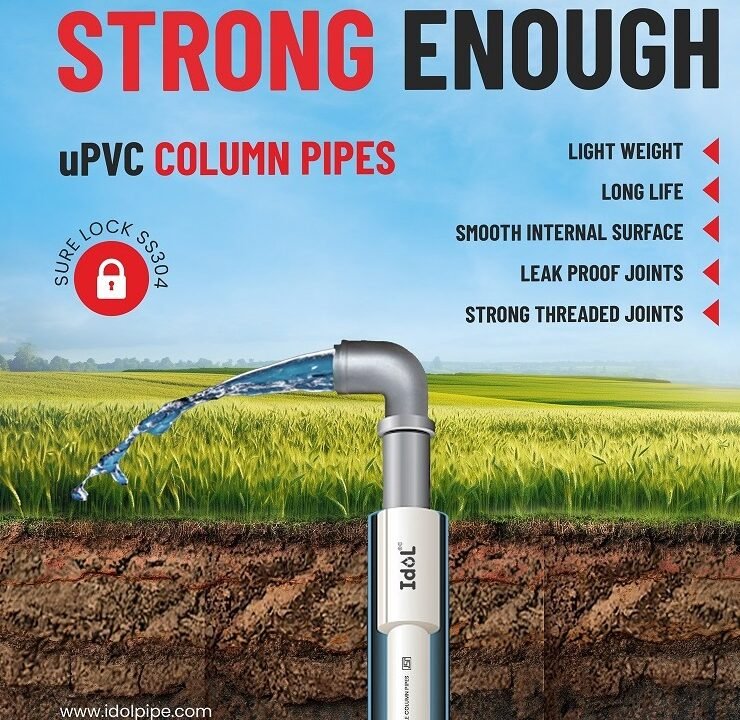

Enter Idol uPVC Column Pipes, a solution engineered specifically to conquer the harsh realities of underground water extraction. As their bold new campaign states, these pipes are built with one defining characteristic in mind: being STRONG ENOUGH for the job.

But what does “strong enough” really mean when we are talking about hundreds of feet underground? Let’s dive into why Idol uPVC Column Pipes are setting a new standard for plumbing, drainage, and specifically, agriculture.

The Invisible Battle Underground

When a submersible pump is lowered deep into a borewell, the column pipe connecting it to the surface faces immense stress. It must support the entire weight of the pump, the weight of the water column inside the pipe, and withstand the intense vibrations caused by the pump’s operation. Furthermore, it has to resist the corrosive nature of groundwater and soil chemicals.

Traditional metal pipes, once the standard, are increasingly failing this test. They rust, they get heavy with scale buildup, and their threaded joints are prone to failure over time.

Idol has addressed these challenges head-on by utilizing high-quality uPVC (Unplasticized Polyvinyl Chloride), engineered with specific features designed for longevity and performance.

Deconstructing the “Idol” Advantage

Looking closer at the specifications of Idol uPVC Column Pipes reveals why they are rapidly becoming the preferred choice for modern irrigation systems. Let’s break down the key features highlighted in their latest showcase:

1. The Game Changer: SURE LOCK SS304 Technology The most critical point of failure in any column pipe system is the joint. If a joint slips or leaks under the immense pressure of a deep well, the entire system can fail, leading to the catastrophic loss of the pump down the borehole.

Idol addresses this with their innovative “SURE LOCK SS304” system. This isn’t just a standard thread. It incorporates a locking mechanism, likely reinforced with SS304 (a high-grade stainless steel known for corrosion resistance), to ensure that once the pipes are joined, they stay joined. This feature provides peace of mind, ensuring that even under heavy load and vibration, the joints remain secure.

2. Leak-Proof and Strong Threaded Joints Building on the Sure Lock technology, the threading itself is engineered for maximum strength. A leak-proof joint is essential not just for structural integrity, but for efficiency. Every drop of water that leaks back into the well through a faulty joint is wasted energy. The pump has to work harder to deliver the same amount of water to the surface, driving up electricity bills. Idol’s precision-engineered joints ensure 100% leak-proof performance.

3. Smooth Internal Surface: The Efficiency Booster While strength is crucial, efficiency is equally important. Metal pipes suffer from corrosion and scale buildup over time, creating a rough interior that causes friction. This friction slows down the water flow, forcing the pump to consume more electricity to maintain the desired output.

Idol uPVC pipes boast a mirror-smooth internal surface that remains smooth throughout their lifespan. This results in near-zero friction loss. The practical benefit for the farmer? A significantly higher flow rate of water using the same pump, leading to substantial energy savings over the years.

4. Light Weight, Heavy Performance Anyone who has installed galvanized iron pipes knows the backbreaking labor involved. They are heavy, difficult to transport, and require significant manpower to install.

Idol uPVC pipes are remarkably lightweight without sacrificing structural integrity. This characteristic drastically reduces transportation costs and makes installation faster and safer. A smaller team can install deeper columns in less time, reducing the overall project setup cost.

5. Long Life: A Legacy Investment Perhaps the most significant advantage of uPVC over traditional metal is its inherent resistance to corrosion. Idol pipes are immune to the rust and electrolytic action that destroys metal pipes underground. They are also highly resistant to various chemicals found in soil and water. This translates to an exceptionally long operational life. Installing Idol pipes is a long-term investment in farm infrastructure, removing the worry of pipe replacement for decades.

The Verdict: Strong Enough for Your Future

In agriculture, reliability is everything. When the sun is beating down and your crops need water, you cannot afford to worry about whether your borewell pipes will hold up.

Idol uPVC Column Pipes have successfully bridged the gap between modern material science and the practical, rugged needs of farming. By combining lightweight design with incredible tensile strength, leak-proof locking technology, and superior hydraulic efficiency, they offer a solution that truly is “STRONG ENOUGH.”

For farmers looking to modernize their irrigation, reduce long-term maintenance costs, and ensure a consistent water supply season after season, choosing Idol is a decision rooted in strength and foresight.

To learn more about specifications and sizing for your specific borewell needs, visit IDOL uPVC column pipes